Bentonite is a naturally occurring clay composed primarily of montmorillonite, a layered alumino-silicate mineral known for its exceptional swelling, absorbency, and binding characteristics. When hydrated, bentonite forms a thixotropic gel, making it an essential functional material across a wide range of industrial applications.

Due to its rheological control, sealing ability, and chemical stability, bentonite is widely used in drilling fluids, foundry molding sands, iron ore pelletizing, civil engineering, and environmental protection systems. Its natural origin and cost-effectiveness further enhance its value in demanding industrial processes.

Oil & Gas Drilling: Used as a key component in drilling fluids to: Stabilize borehole walls, Control fluid loss, Suspend cuttings and cool drill bits.

Foundry & Metal Casting: Acts as a binder in green sand systems, improving: Mold strength, Dimensional stability, Casting surface finish.

Construction & Civil Engineering: Applied for: Slurry walls and diaphragm walls, Foundation sealing and grouting, Groundwater containment and seepage control.

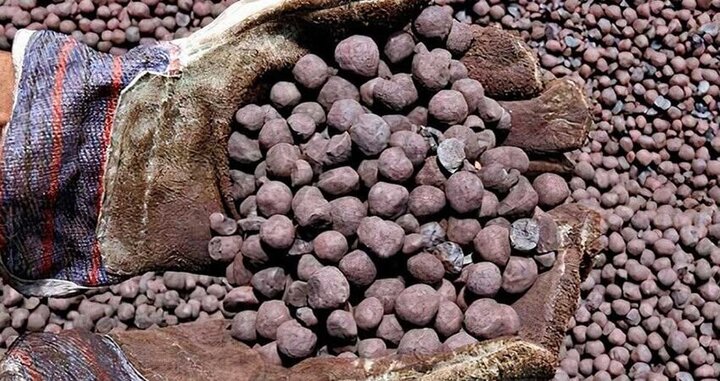

Iron Ore Pelletizing: Functions as a binder to agglomerate iron ore fines into mechanically stable pellets for steelmaking.

Agriculture & Livestock: Applied as: Soil conditioner to improve moisture retention, Binder in animal feed pellets (application-specific grades).

Consumer & Specialty Uses: Selected refined grades are used as absorbents in: Cat litter (odor control), Personal care products (limited cosmetic applications).

We supply industrial-grade bentonite with consistent and reliable performance, supported by strict quality control.

Our capabilities include:

Q: What is bentonite mainly used for?

A: Bentonite is used in drilling fluids, foundry molds, construction sealing, environmental liners, and iron ore pelletizing due to its swelling and binding properties.

Q: What is the difference between sodium and calcium bentonite?

A: Sodium bentonite exhibits significantly higher swelling and is preferred for sealing and drilling. Calcium bentonite offers lower expansion and is used where controlled absorbency is required.

Q: How is bentonite supplied?

A: It is supplied as powder or granules in bags, jumbo bags, or bulk. Dust-controlled and pelletized forms are available.

Q: Is bentonite suitable for food or pharmaceutical use?

A: Only specifically processed and certified grades should be used in food or pharmaceutical applications. Standard industrial grades are not intended for such use.

Q: How should bentonite be stored?

A: Store in a dry, covered environment to prevent moisture uptake and maintain flowability.

Applications

Let's get in touch and explore business opportunities

Connect With Us