Calcium Carbonate-Functional additives that powers industries

In the vast world of industrial materials, very few substances are as versatile and widely used as Calcium Carbonate (CaCO₃). It is a an Additive that quietly powers some of the most essential sectors—paints, plastics, rubber, paper, cosmetics, pharmaceuticals, and more.

Whether it’s improving whiteness in paints, enhancing strength in polymers, reducing pulp usage in paper, or acting as a mild abrasive in toothpaste, Calcium Carbonate is the silent performer behind superior performance and cost-efficiency.

At 20 Microns Nano Minerals Ltd., we don’t just provide raw calcium carbonate. We engineer surface-modified, Nano-sized, and application-optimized CaCO₃ grades that are tailored to meet specific industrial needs—providing measurable improvements in process ability, aesthetics, mechanical properties, and regulatory compliance.

What is Calcium Carbonate?

Calcium Carbonate is a naturally occurring compound composed of calcium, carbon, and oxygen (CaCO₃). It exists in various geological forms, including:

- Limestone

- Marble

- Chalk

There are two main industrial forms:

| Type | Description | Use Case |

|---|---|---|

| GCC (Ground Calcium Carbonate) | Mined and mechanically ground; retains natural crystalline structure | Used where high brightness, particle size control, and low cost are needed |

| PCC (Precipitated Calcium Carbonate) | Synthetically processed for precise particle control | Used in high-end applications needing Nano sizes, ultra-whiteness, or narrow distribution |

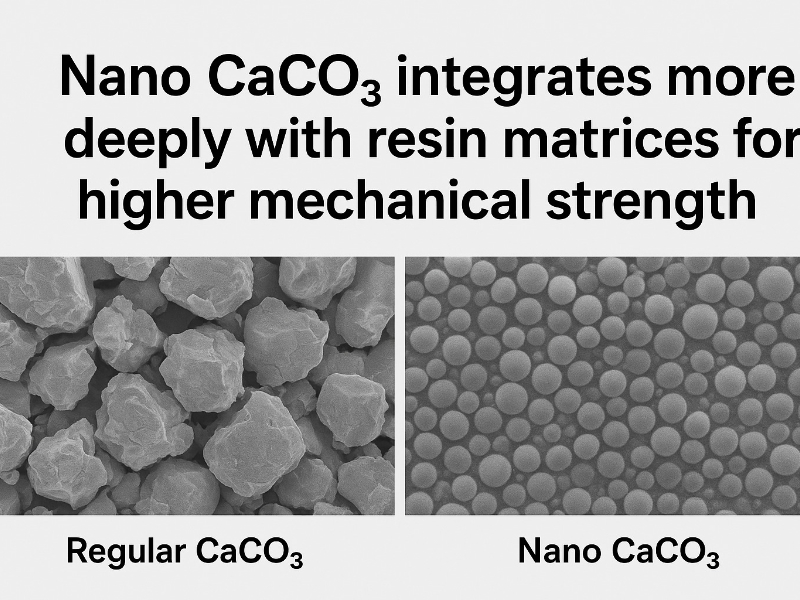

Nano Calcium Carbonate, an advanced form of PCC, is engineered for superior surface area and dispersion—especially beneficial in paints, plastics, rubber, and sealants.

Key Properties of Calcium Carbonate

| Property | Why It Matters |

|---|---|

| High Whiteness & Brightness | Essential for aesthetic coatings, papers, and master batches |

| Thermal Stability | Withstands high temperatures in plastics, rubbers, and composites |

| Particle Size Control | Tailors flow, packing density, and surface texture |

| Surface Reactivity | Enables surface treatment for better resin/pigment compatibility |

| Eco-Safety & Inertness | Non-toxic and widely accepted in food-grade and cosmetic applications |

1. Paints & Coatings

Why It’s Used:

- Boosts opacity and whiteness in decorative and industrial paints

- Improves viscosity, levelling, and film formation

- Offers Gloss and Matt Properties in paint and plastics

Benefits:

- Reduces TiO₂ usage without sacrificing coverage

- Helps control gloss, viscosity, and drying behaviour

20 Nano's Solution:

We offer Nano-treated, hydrophilic/hydrophobic calcium carbonate to suit water- and solvent-based paints.

2. Plastics & Polymers

Why It’s Used:

- Enhances rigidity, HDT (heat deflection temperature), and dimensional stability

- Reduces shrinkage and warpage

- Improves printability and impact strength in PP, PE, PVC, etc.

Benefits:

- Cost reduction without quality compromise

- Allows faster cooling in extrusion and injection moulding

20 Nano’s Edge:

Our surface-modified Nano CaCO₃ has tight particle size control, better dispersion, and excellent mechanical reinforcement.

3. Rubber and Elastomers

Why It’s Used:

- Works as a reinforcing filler

- Controls modulus, hardness, and abrasion resistance

- Reduces compound cost while maintaining elasticity

Example Applications:

- Rubber hoses, tires, seals, gaskets, and conveyor belts

20 Nano’s Advantage:

Our fine-grade CaCO₃ grades offer improved dispersion, filler-resin interaction, and longer tooling life during processing.

4. Paper and Packaging

Why It’s Used:

- Acts as both a filler and coating pigment

- Improves smoothness, brightness, and ink receptivity

- Reduces reliance on wood pulp and optical brighteners

5. Personal Care & Cosmetics

Applications:

- Face powders, foundations, and sunscreens (as texture agent and carrier)

- Toothpaste (as a mild abrasive)

Why It’s Preferred:

- Biocompatible, non-irritating, and free from harmful additives

Why Choose 20 Nano’s Calcium Carbonate Additives as Solutions?

1. Advanced Particle Engineering

We manufacture:

- Ultrafine and Nano calcium carbonate <100 nm

- Narrow particle distribution

- Advance surface treatments for better bonding and dispersion

2. Application-Focused Customization

We develop grades specific to:

- Paints (gloss vs. matte systems)

- PVC pipes vs. films

- Cosmetic-safe, pharma-grade CaCO₃

3. Eco-Compliant and High-Purity

- Customized packaging

Anchor Text Links:

- 1. See our full Calcium Carbonate product range –

https://www.20microns.com/products/calcium-carbonate - 2. Learn about our custom mineral processing capabilities –

https://www.20microns.com/services - 3. Explore 20 Nano’s solutions for plastics

https://www.20nano.com/plastics

Real-World Case Study: Plastics Masterbatch Success

A masterbatch manufacturer in Gujarat was facing dispersion issues and lower tensile strength due to substandard CaCO₃.

We supplied a surface-modified Nano calcium carbonatetailored for LDPE.

Result: 35% improvement in pigment dispersion, 22% higher tensile strength, and a 15% cost saving by reducing resin load.

Final Thoughts

Calcium Carbonate is far more than a cost-saving filler—it’s a multifunctional Functional additive that can be engineered to unlock performance and value across industries.

At 20 Microns Nano Minerals Ltd., we believe in materials science based chemistry as a tool to drive industrial efficiency, innovation, and sustainability. Whether you are in paints, plastics, rubber, or personal care—our team of chemists, application experts, and technical marketers can help you design the right solution using the right calcium carbonate.