Talc – The Ultimate Functional Additive for Industrial Performance

Talc, though recognized as the softest mineral on Earth, plays a critical role in enhancing industrial performance. As a functional additive, it serves as an effective performance filler, anti-blocking agent, nucleating agent, and rheology modifier. Owing to its unique physicochemical properties, talc is widely utilized across various industries, including plastics, paints and coatings, cosmetics, pharmaceuticals, and paper manufacturing.

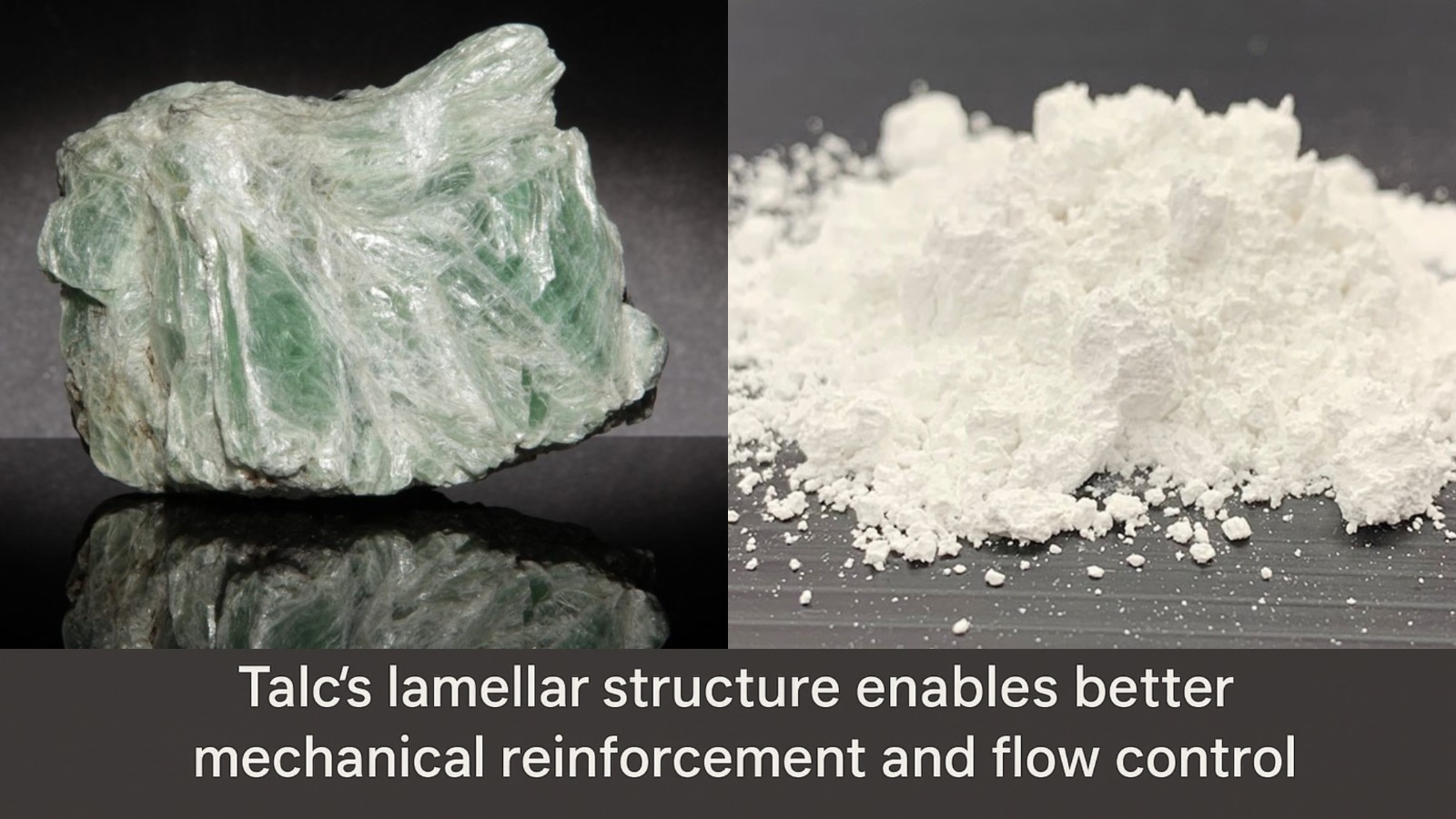

Talc’s industrial value is primarily attributed to its lamellar (plate-like) morphology, hydrophobic surface characteristics, and chemical inertness. These inherent properties enable manufacturers to enhance product performance by improving mechanical strength, dimensional stability, barrier properties, and surface finish.

At 20 Microns Nano Minerals Ltd., we specialize in the development and production of ultrafine, and surface-modified talc grades. Our engineered talc products are designed to optimize performance by enhancing product quality, improving process ability, and reducing overall production costs, while adhering to stringent international quality and regulatory standards.

What is Talc?

Talc is a naturally occurring hydrated magnesium silicate with the chemical formula Mg₃Si₄O₁₀(OH)₂. On the Mohs hardness scale, it ranks as the softest mineral (1/10), yet its industrial applications are incredibly powerful.

Key Characteristics of Talc:

- Smooth, greasy feel

- Hydrophobic (water-repellent) nature

- Chemically inert with high compatibility

- Excellent barrier and anti-caking properties

- Plate-like morphology for improved reinforcement

These properties make talc an ideal performance enhancer in engineered materials where thermal stability, smooth finish, and controlled shrinkage are critical.

Key Properties of Industrial Talc

| Property | Why It’s Valuable |

|---|---|

| Lamellar Structure | Improves mechanical reinforcement, stiffness, and barrier effect |

| Hydrophobic Nature | Enhances water resistance, dispersibility in polymers |

| Thermal Stability | Useful in high-temperature processing (up to 900°C) |

| Ultra-Fineness | Boosts dispersion, gloss, and tactile properties |

Major Industrial Applications of Talc

1. Talc for Plastics & Polymers

Talc is widely used in plastics as a filler and nucleating agent to improve mechanical and processing performance.

Benefits:

- Increases stiffness, HDT (Heat Deflection Temperature), and impact resistance

- Reduces shrinkage and warpage in MOULDED parts

- Acts as a nucleating agent in polypropylene

Applications:

- Automotive dashboards and bumpers

- Home appliances

- PP/PE food packaging films

At 20 Microns Nano, we supply ultrafine, surface-treated talc tailored for polyolefins, PVC, and engineering plastics. Our grades improve flow, printability, thermal stability, and dimensional control.

2. Talc for Paints & Coatings

Talc enhances both aesthetics and durability in paints.

Why It’s Used:

- Provides matting effect and smooth finish

- Improves stain blocking and weather resistance

- Acts as a rheology and anti-settling agent

20 Microns Advantage:

Our talc grades are designed for excellent dispersion in both water-based and solvent-based paints, ensuring longer suspension stability, reduced sagging, and better scrub resistance.

3. Talc for Cosmetics & Personal Care

For decades, talc has been trusted in personal care formulations due to its safety and performance.

Applications:

- Body and face powders

- Foundations, blush, and eyeshadows

- Deodorants and skincare products

Why Talc is Ideal:

- Provides soft, silky texture

- Absorbs excess oils and moisture

- Non-irritating and dermatologically safe

Our cosmetic-grade talc is asbestos-free, microbiologically pure, and globally compliant (USP, IP, etc.), making it safe for daily use.

4. Talc for Paper & Pulp

Talc plays a dual role in the paper industry as both a filler and process aid.

- Improves opacity, printability, and smoothness

- Used as a coating pigment

- Contributes to the mitigation of pitch and stickies during paper production

5. Talc for Pharmaceuticals & Nutraceuticals

In the pharmaceutical and nutraceutical industries, talc is widely used as a functional excipient due to its inertness, softness, and lamellar structure.

- Serves as a lubricant in tablet formulations, minimizing friction during tablet compression and ejection

- Acts as an anti-caking agent in powdered formulations, enhancing flowability and preventing clumping

- Contributes to tablet uniformity and surface finish by promoting even die filling

- Used in dusting powders and topical applications for its smooth texture, absorbency, and skin compatibility

Why Choose 20 Microns Nano’s Talc?

At 20 Microns Nano Minerals Ltd., our talc goes beyond conventional fillers — it is a scientifically engineered solution.

Application-Specific Grades

- Tailored grades for injection moulding, film extrusion, coatings, and personal care

- Consistent quality for performance-driven industries

Conclusion

Talc is no longer just a mineral—it’s a smart performance additive transforming product capabilities across industries. From plastics needing heat resistance, to coatings requiring superior stability, to personal care products where softness and purity are essential, our nano and ultrafine talc solutions are raising the bar for performance and reliability.

At 20 Microns Nano Minerals Ltd., we offer engineered mineral innovations that combine science, technology, and quality, empowering industries worldwide to achieve better results with every formulation

Anchor Recommendations:

- Explore our Nano Talc product range

- Learn more about our paint and plastic applications

- Connect with us for custom product solutions