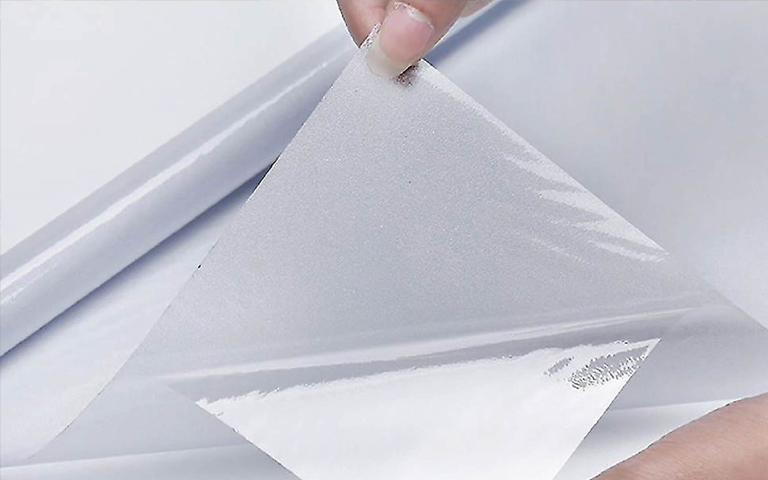

The theory of anti-blocking is that varied particle shapes of diatomite particles protrude from, or are at the surface of the polyethene film. The particles of Aomorphlos, Klearblock & Talc HFM15/HFM 25 are extremely efficient for this application in all types of polyolefin films including LLDPE, metallocene PE and PP. Depending on the type of resin used to make the film and the end-use application the amount of anti-block required usually ranges from 0.2% to 0.5% by weight of the resin. Due to the critical nature of incorporating a solid into a solid plastic film, our products meet exacting quality. Anti-blocking additives are most important for film applications. Antiblocking additives help to reduce the blocking between polymer surfaces.

AMORPHLOS an efficient functional additive is having unique irregular particle shapes, tight particle size distribution, bright & white colour and refractive index.

KEY FEATURES:

- Antiblock Additives in Polyethylene Film Offer

- Low Haze

- Clarity

- AntiBlocking & Low COF

- Fast Melt Fracture Elimination

- Efficient & Versatile

- Minimum Loading

- Cost Effective