Delaminated Clay in Rubber products :

20 Microns Limited is India’s largest producer of white minerals offering innovative products in the field of Functional fillers, Extenders, and Specialty chemicals. Based on a profound understanding of diverse industrial requirements, the company has empowered its clients with customized products based on their specific requirements.

20 Microns Nano Minerals Limited a subsidiary of 20 Microns Limited and is a leading manufacturer of ultra-fine industrial minerals and specialty chemicals in India. Owing to well-equipped laboratories and the most advanced control instruments, 20 Microns produces minerals of the highest standard of quality and consistency. A dedicated R&D center is the focal point of innovations that leads to the formation of advanced quality products. Our exceptional product quality is supported by our excellence in manufacturing capability and technical support service network across the country.

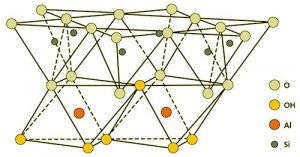

20 Microns Nano Minerals Limited is expertized in manufacturing a wide range of high-performance clay. In general, Kaolin is a (1:1) aluminosilicate with the platy structure having the chemical formula Si4Al4O10(OH)8. In a kaolin structure, a layer of tetrahedral silica rings is bound to an adjacent layer of octahedral alumina through hydrogen bonding. An individual kaolin particle has the shape of a hexagonal plate.

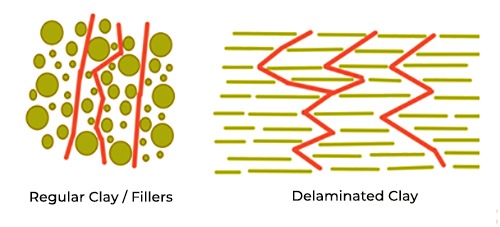

Delaminated clay is one such specially engineered Clay manufactured by 20 Microns Nano Minerals Limited in the country. Delamination of kaolin is accomplished by the specially controlled mechano-chemical process without fracturing its original plate size. In this process, the Kaolin plates are delaminated delicately in specially designed equipment under controlled conditions so as to avoid kaolin plate fractures. The platy structure of Delaminated clay (Delam 802) with increased but controlled aspect ratio improves the impermeability characteristic that contributes towards an effective barrier to transmission of gases, vapors, and liquids across a rubber matrix.

Delaminated clay has specific particle sizes and structures for meeting various critical application requirements. It improves upon specific properties for demanding applications like high-performance tyre inner liners, inner tubes, hoses, and other engineered rubber products. The addition of Delaminated clay in halobutyl-based inner liner compounds helps to meet evolving market needs for lighter-weight tyres designed for lower rolling resistance & improved fuel economy.

The specific features of delaminated clays that impact rubber compounds are:

- Clay morphology

- Kaolin particle size

- Particle size distribution

- Crystallinity or degree of order of kaolinite.

- Plate aspect ratio

The platy structure of Delaminated clay ( Delam 802 ) with increased but controlled aspect ratio improves impermeability characteristic that contributes towards an effective barrier to transmission of gases, vapors, and liquids across rubber matrix.

The aspect ratio in rubber influences on following properties :

- Barrier properties

- Dispersibility

- Compound viscosity

- Reinforcement of rubber compounds

The automotive tyre is a composite product of multiple components – mostly of specially formulated rubber compounds that strike a balance between contrasting properties. The performance of an Innerliner compound in a tubeless Radial tyre is very critical for retaining air pressure during long haulage as well as during running at higher speeds. The addition of Delaminated Clay further improves the air retention capability of innerliners. In the process, it supports tyre manufacturers to downgauge innerliner thickness further without compromising overall air retention capability. In general, it is a step forward towards the reduction of tyre’s rolling resistance and improving fuel efficiency.

This innovative and sustainable product provides solutions to today’s challenging issues in various applications. Overall, the advantages of 20 Microns Nano Minerals’ Delaminated Clay material ( Delam 802) in rubber products may be summarized below :

- Natural & Environment-friendly sustainable material

- Excellent impermeability to Air, N2 & O2 and other gases / liquids

- Restricts air bubble see pages due to its platy structures, thus improving Barrier properties for Tyre Inner liner

- Inner liner thickness can be down-gauged for improved RR

- Limits O2 diffusion through carcass preventing steel cord corrosion in tyre and conveyor belts

- Supports in restricting liquid transmission across rubber matrix in high-performance hoses and gaskets

Hi, this is a comment.

To get started with moderating, editing, and deleting comments, please visit the Comments screen in the dashboard.

Commenter avatars come from Gravatar.